DISCOVERING THE COOPER'S CRAFT

The cooper's job in Champagne, as elsewhere, is a specialised craft that involves making and maintaining barrels, casks and other wooden containers used for ageing wine, particularly champagne.

We reveal the secrets of this creative craft.

OUR PARTNER

THE VIARD TONNELLERIE

Domaine Fagot has worked closely with Tonnellerie Viard in Cauroy-lès-Hermonville since its creation.

The coopers select a regional supply of this wood, from the Argonne forest and the Montagne de Reims, which accounts for 80% of their selection of oak wood. Their aim is to enhance the value of nearby forests and provide their customers with traceability and local origin. For the winegrowers, this represents a guarantee of quality and a selling point for their ‘cuvées sous-bois’ (Champagne made with oak barrel) with their customers.

PRODUCTION SECRETS

Where the barrel comes from: the oak must be at least 120 years old and 50 cm in diameter.

Barrels take time to make, and there are many stages in the process where wood, wind, rain and fire all play their part: all these natural elements contribute to the creation of a barrel, without the use of any synthetic products.

THE LOG SPLIT

One oak tree produces an average of 1.5 m3 of logs for stave wood (split oak).

10 m3 of logs are needed to produce 2 m3 of staves from which the pedicles will be drawn to produce 20 casks (205 to 288L pieces).

PEDICLE DRYING

The pedicles are left to rest in the open air for 3 to 4 years, in the sun and exposed to the elements, in order to remove the bitterness and astringency of the wood and, at the same time, refine the aromas and tone of the wood to achieve perfect maturity. The ultimate aim is to preserve the finesse and elegance of the wines made in barrel.

BARREL CONSTRUCTION

The pedicles are transformed into staves. Around thirty staves are needed to make the shell of the barrel, while the bottoms provide a watertight seal. Galvanised hoops hold the staves together, as well as the bottoms.

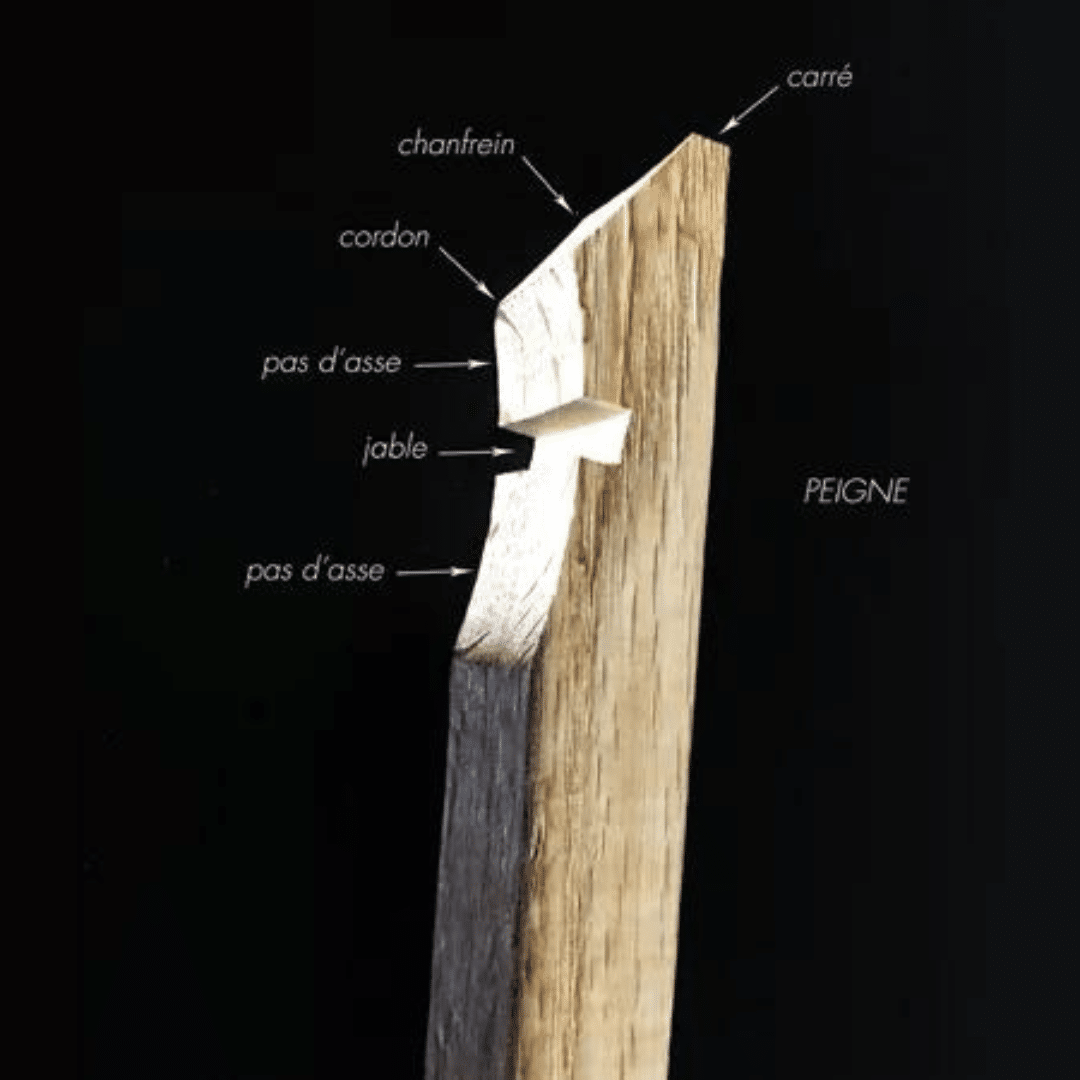

To go from pedicle to stave, here are the different stages:

"ECOURTAGE" : to produce in volume, the pedicles are given a chosen length, which must be the same for everyone.

"DOLAGE" : This stage consists of giving the outer curve which corresponds to the circumference of the barrel.

"CREUSAGE" : The inside of the stave will be hollowed out to give the first internal shape.

"JOINTAGE" : This is a delicate operation that will give the stave a ‘bouge’ width (middle of the barrel) and a head width with a joint inclination to give a perfect roundness.

This is followed by the ‘’CINTRAGE‘’ stage, in which the dry heat of the wood fire is used to make the shell of the barrel watertight. The barrel is presented in a ‘robe’, also known as a ‘rose’. Once assembled, the barrel is heated inside to bend the wood, which makes up the body of the barrel.

"HEATING" the barrel is an essential stage for the winemaker. It is carried out according to each winemaker's requirements, to give the wine the woody character, whether pronounced or discreet.

"BOUSINAGE", the final stage in the toasting process, allows the barrel to reveal its silky, elegant aromas, such as vanilla, lime blossom, coffee, toast and spice, for future champagnes. Tonnellerie Viard has the particularity of carrying out a slow and gentle toasting at low temperature.

"ROGNAGE" This operation prepares the ends of the staves for the bottoms. The jable forms the groove that will receive the bottom. For the bottom pieces, the timbers are placed next to each other to hold the pieces together with stainless steel dowels. A sheet of rush is placed between each piece of wood to ensure a perfect seal.

To "FONCAGE", we remove the standing hoops to free the staves. A paste made from buckwheat flour, ash and water is placed in the bottom of the jable to create a perfect seal.

The "CERCLAGE" The first hoops used to prepare the casks were wide and thick, known as ‘mould hoops’. Subsequent hoops are made of galvanised strip and driven in using the ‘chaser’. Chestnut wood hoops can be added to protect the casks and make it easier to ‘stack’ them in the cellars.

And for the finish, the "FUTAILLE" is water-tested to ensure there are no defects. Any solid particles trapped against the walls are also removed. After these operations and a thorough rinse, the cask is sanded.

Would you like to find out more about the art of barrel-making? The Tonnellerie Viard has been open to tourists for a number of years.

Don't hesitate to visit them: